Spanish manufacturers are capitalizing on this trend by establishing distributed production networks that can respond quickly to local demand. Photo by Osman Talha Dikyar on Unsplash

Spain is positioning itself as a key player in Europe’s additive manufacturing renaissance, with Valencia set to host the 10th European Additive Manufacturing Conference this October, a milestone event celebrating a decade of innovation across the continent. This gathering symbolizes more than just technological progress; it represents Europe’s commitment to revolutionizing how we think about production.

The momentum behind this transformation extends far beyond Europe’s borders. As highlighted in a recent World Economic Forum analysis on 3D printing’s role in accelerating sustainable manufacturing, the technology is fundamentally reshaping global production paradigms. The WEF’s insights on how additive manufacturing reduces waste, enables local production, and supports circular economy principles align perfectly with Europe’s ambitious sustainability agenda.

From Waste to Wonder: The Circular Economy Connection

In 2025, the industry is expected to focus significantly on sustainable manufacturing practices as companies prioritize decarbonization and circular economy solutions. European manufacturers are increasingly embracing 3D printing not just as a production tool, but as a cornerstone of the circular economy that the European Commission expects to help avoid €22 billion in environmental damage by 2030.

The transformation is already underway. Spanish companies like Bronymec are leading the charge by applying Design for Additive Manufacturing principles that optimize products for functionality while dramatically reducing waste. Their approach demonstrates how European innovation is moving beyond simple printing to comprehensive sustainable design philosophy.

Breaking the Traditional Manufacturing Mold

Traditional manufacturing has long operated on a “take-make-dispose” model that generates enormous waste. 3D printing is making manufacturing more flexible, efficient, and adaptable than ever, fundamentally challenging this wasteful approach. Instead of subtracting material from larger blocks, as in traditional machining additive manufacturing builds products layer by layer, using only the material needed.

This precision has profound implications. Where conventional automotive manufacturing might waste up to 90% of raw materials, 3D printing can achieve near-zero waste production. European automotive companies are particularly excited about this potential, with researchers exploring how end-of-life vehicle plastics can be transformed into new components through additive manufacturing.

Materials Innovation: Europe’s Green Edge

The most exciting developments are happening in materials science. European researchers are pioneering the use of recycled plastics, plant-based polymers, and biodegradable materials as 3D printing feedstock. The CircularSeas project, part of the EU’s Circular Economy initiative, is turning maritime plastic waste into valuable 3D printing materials, creating a closed loop that benefits both oceans and industry.

What makes this particularly compelling for European manufacturers is the dual benefit: reduced material costs and enhanced environmental credentials. Companies are discovering that sustainable materials often perform as well as traditional ones while opening new market opportunities among environmentally conscious consumers.

Local Production, Global Impact

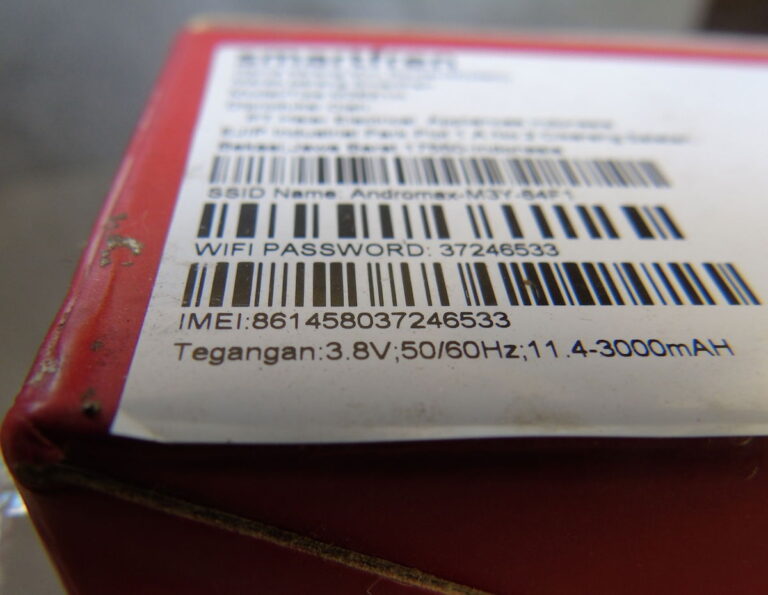

3D printing is no longer confined to prototyping; instead, it is increasingly utilized for producing small production lots of industrial products, enabling a fundamental shift toward localized manufacturing. This decentralization has particular resonance in Europe, where concerns about supply chain resilience have grown following recent global disruptions.

Spanish manufacturers are capitalizing on this trend by establishing distributed production networks that can respond quickly to local demand while minimizing transportation emissions. This model proves especially valuable for producing spare parts on-demand, eliminating the need for extensive warehousing and reducing the carbon footprint of logistics.

Looking Forward: Valencia and Beyond

As Valencia prepares to welcome the European additive manufacturing community this October, the city embodies Europe’s approach to sustainable innovation, balancing technological advancement with environmental responsibility. The conference will showcase how 3D printing is transforming industries from aerospace to healthcare, all while advancing the continent’s ambitious sustainability goals.

The convergence of European regulatory frameworks, innovative materials science, and growing market demand creates an unprecedented opportunity. Companies that embrace additive manufacturing today aren’t just investing in new technology; they’re positioning themselves at the forefront of a manufacturing revolution that promises to reshape how we create, consume, and care for our planet.

Europe’s commitment to sustainable 3D printing represents more than technological progress, it’s a blueprint for responsible innovation that other regions are watching closely. As Spanish and European companies continue to lead this transformation, they’re proving that environmental responsibility and economic success aren’t just compatible; they’re inseparable in the future of manufacturing.